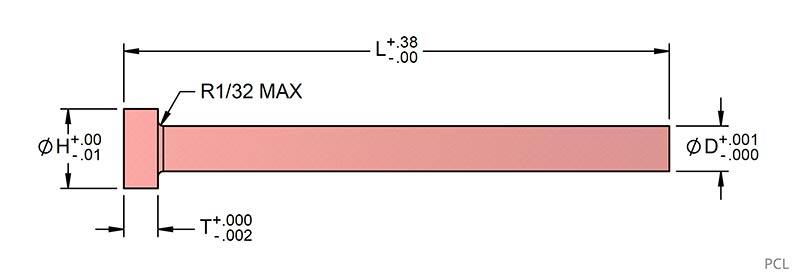

- Unit of measure: Inch

- Beryllium Free

- Material: MoldStar® 150

- Hardness 90-98 Rockwell "B" (11-21 Rockwell "C")

- Higher tensile strength than P-20 tool steel

- Retains the inherent corrosion resistance of copper

- Reduces post-mold shrinkage problems

- Requires no additional heat treatment

- Six times better conductivity than steel

- Two times better conductivity that beryllium copper core pins

PCS Company offers beryllium free copper alloy Performance Core Pins® as the alternative for steel pins or copper alloy pins containing beryllium. Choose from 61 sizes with 18 diameters ranging from 3/32” to ¾” and lengths of 3”, 6”, 14” and 20”. The Performance Core Pins are precision made from beryllium free copper alloy that dramatically increases the rate of heat transfer when compared to conventional steel core pins. The Performance Core Pins provide heat transfer results of 6-10 time better than steel core pins and twice the rate of beryllium-copper alloy core pins. Performance Core Pin can be titanium nitride (TiN) coated or chrome plated to provide wear resistance for abrasive filled resins applications. Titanium Nitride (TiN) coating is recommended on a Performance Core Pin in the sleeve application, although uncoated Performance Core Pins have worked well because of the reduced coefficient of friction between the copper alloy pin and the steel sleeve. For Custom Performance Core Pins, contact PCS Company at customcomponents@pcs-company.com.